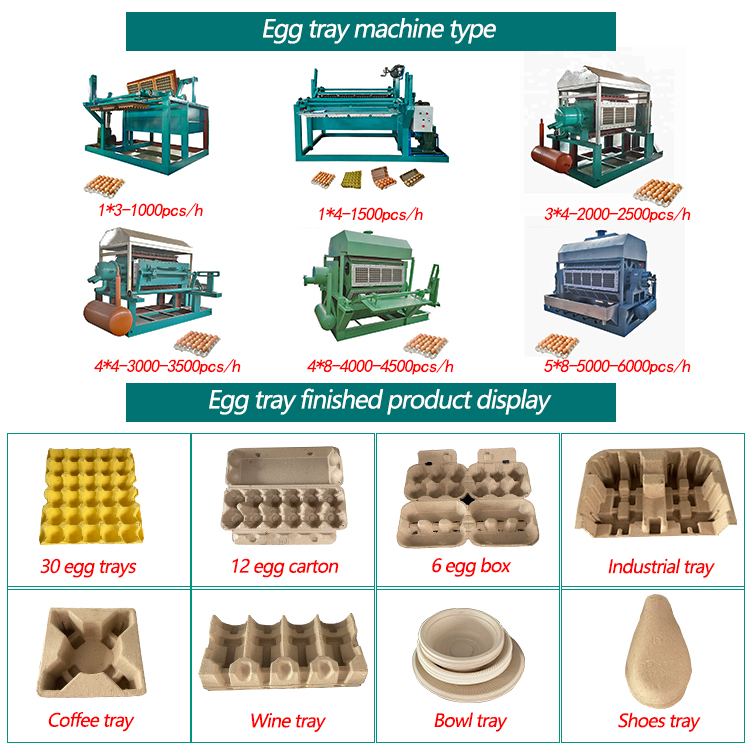

1. A maara akara mmepụta Pulp dị ka akara akwa maka iji ya mee ihe n'ọtụtụ ebe na tray àkwá.

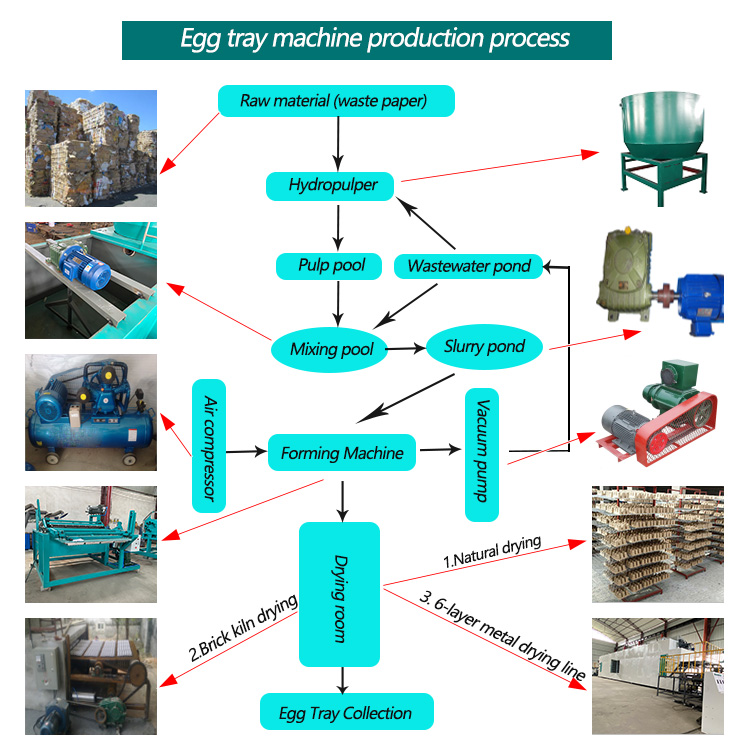

2. Ahịrị mmepụta nke Pulp Moulding, nke na-eji akwụkwọ mkpofu, katọn, ihe fọdụrụ n'ime igwe mpempe akwụkwọ, site na hydraulic pulper, ngwakọta na-eme pulp dị oke arọ, a na-etinye pulp ahụ site na oghere nke ihe eji akpụ ígwè pụrụ iche ka ọ bụrụ ngwaahịa mmiri mmiri, site na ihicha ya, ma na-akpụ ya ka ọ bụrụ ngwaahịa emechara.

3. Usoro nhazi nke Pulp Moulding Line na-eji mmiri e megharịrị emegharị eme ihe, ọ naghịkwa ebute mmetọ mmiri ma ọ bụ ikuku. Enwere ike ịmegharị ngwaahịa nkwakọ ngwaahịa emechara emecha mgbe ejiri ha mee ihe n'ebe nchekwa, ibuga, na ire ere. Mgbe e gbusịrị ha, ọ dị mfe ịgbari ha dị ka akwụkwọ, ọbụlagodi ma a tụfuo ha n'ime gburugburu ebe obibi.

4.Ahịrị mmepụta ihe eji akpụ akpụ akpaka nwere ike ịbụ mmepụta nke ọtụtụ akpa nri dị iche iche, tray àkwá, igbe nri ehihie na ihe ndị ọzọ.

| Ụdị Igwe | 1 * 3/1 * 4 | 3 * 4/4 * 4 | 4 * 8/5 * 8 | 5 * 12/6 * 8 |

| Mmepụta (p/h) | 1000-1500 | 2500-3000 | 4000-6000 | 6000-7000 |

| Akwụkwọ Mkpofu (kg/h) | 80-120 | 160-240 | 320-400 | 480-560 |

| Mmiri (kg/h) | 160-240 | 320-480 | 600-750 | 900-1050 |

| Ọkụ eletrik (kw/h) | 36-37 | 58-78 | 80-85 | 90-100 |

| Mpaghara Ụlọ Ọrụ | Afọ 45-80 | 80-100 | 100-140 | 180-250 |

| Ebe Ịkpọ nkụ | Enweghị isi | 216 | 216-238 | 260-300 |

Draịvụ servo dị elu nke ọma, arụmọrụ dị elu na ahịrị nkụ na-echekwa ike.

1, Jiri servo moto reducer nke na-eme ma na-ebufe ya iji hụ na ọ na-arụ ọrụ ngwa ngwa ma na-aga nke ọma.

2, Jiri koodu nchekwa zuru oke iji nweta mmezi ziri ezi.

3, Ojiji nke ihe owuwu mgbanaka ọla nchara na nke na-agbanwe agbanwe dabara adaba maka usoro iwepụ mmiri ngwaahịa.

4, Ojiji nke usoro igwe iji hụ na ebu ahụ mechiri emechi n'akụkụ abụọ ahụ nke ọma.

5, Ike buru ibu; Mmiri dị obere; Chekwaa ọnụ ahịa nke ịkpọ nkụ.

1. Sistemụ mmịpụta

2. Sistemụ nhazi

3. Sistemụ nkụ

(3) Ahịrị nkụcha ọhụrụ nke nwere ọtụtụ oyi akwa: Ahịrị nkụcha ígwè nke nwere oyi akwa isii nwere ike ịchekwa ike karịrị 30%

4. Nkwakọ ngwaahịa enyere aka emechara

(2) Baler

(3) Onye na-ebufe mbufe

-

Akwụkwọ akwụkwọ achara na-eto eto na-eme tree akwa na akpaaka ...

-

Akwụkwọ mkpofu Imegharị Akwa Katọn Igbe Akwa Tray M...

-

YB-1 * 3 igwe na-eme tray àkwá 1000pcs/h maka bu...

-

Akpaka akwụkwọ pulp egg tre mmepụta akara /...

-

Akwa tray pulp ịkpụzi igwe maka obere ...

-

Akpaka akwụkwọ mkpofu pulp àkwá tre ime igwe ...